The world of electronics is vast and ever-evolving, with PCB assembly being one of its most crucial components. This guide aims to take you from a novice to an adept assembler, providing you with valuable insights and practical tips. Let’s dive in!

Introduction

Printed Circuit Board (PCB) assembly is the cornerstone of almost every electronic device we use today. From the smartphone in your pocket to the microwave in your kitchen, PCBs are everywhere. For beginners, understanding PCB assembly can be the gateway to a rewarding career or a fulfilling hobby in electronics. This section will introduce you to the fascinating world of PCB assembly and highlight its significance in modern electronics.

Understanding PCB Assembly

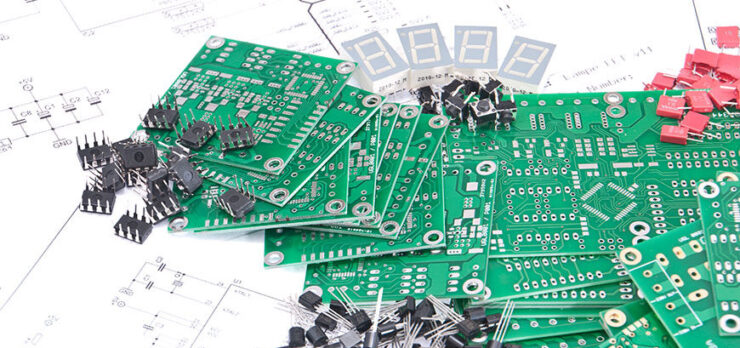

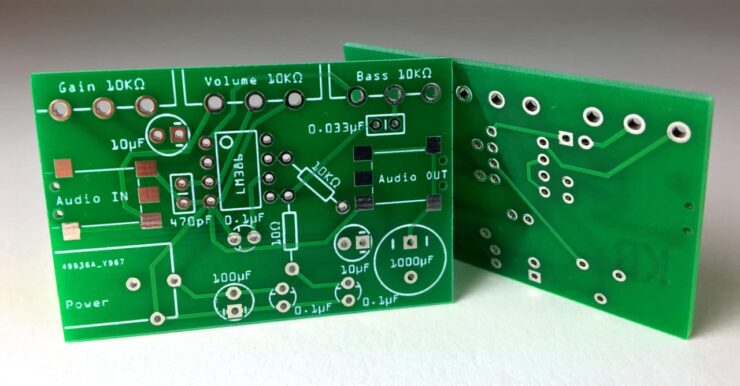

At its core, PCB assembly is the process of attaching various electronic components to a PCB to make a fully functioning electronic circuit. Two primary methods dominate this field: through-hole and surface-mount. Through-hole components have pins that are inserted into holes on the PCB, while surface-mount components are placed directly onto the PCB surface. Each method has its advantages and applications, which we’ll delve into, helping you grasp the nuances of both.

Basic Components and Tools

Before you start assembling, it’s essential to familiarize yourself with the basic components like resistors, capacitors, and ICs. Each component plays a unique role in the circuit. Equally important are the tools of the trade. A soldering iron, flux, solder wire, and desoldering tools are fundamental. This section will provide a comprehensive list of components and tools, ensuring you’re well-equipped to begin your assembly journey, so that in the end you could do it like professionals from Vinatronic.

Preparing the Workspace

Every craftsman knows the importance of a well-organized workspace, and for PCB assemblers, this is no different. A cluttered workspace can lead to misplaced components, errors in assembly, and even potential damage to the components themselves. Precision is paramount in PCB assembly, and an organized workspace promotes this precision. Begin by ensuring you have an anti-static mat.

Static electricity can damage sensitive electronic components, and this mat helps mitigate that risk. Organize your components in labeled containers or trays. Not only does this prevent loss, but it also speeds up the assembly process as you won’t waste time searching for parts.

Ensure adequate lighting in your workspace; a well-lit area reduces the strain on your eyes and helps in identifying components and reading the fine print on them. Lastly, keep your tools within arm’s reach and organized. This setup ensures that your focus remains on the assembly, boosting productivity and reducing potential errors.

Safety Precautions

The world of electronics, while fascinating, comes with its set of hazards. Safety should always be the top priority. The risks associated with PCB assembly include potential burns from a soldering iron that’s often heated to several hundred degrees. Then there’s the danger of tiny components or solder splashes flying into your eyes.

Always wear safety goggles to protect your eyes from such hazards. Gloves can help prevent burns and also protect against any toxic substances that might be present on the PCB or components. Proper ventilation is crucial, especially when soldering.

The fumes from the solder and flux can be toxic when inhaled. Ensure your workspace is well-ventilated, and consider using a fume extractor or wearing a mask. Remember, while the goal is to create a functional PCB, it should never come at the cost of your health and safety.

Reading Schematics and PCB Layouts

Reading schematics is akin to deciphering a blueprint of a circuit’s architecture. Just as a roadmap guides a traveler, a schematic guides an assembler through the intricate pathways of connections. This section will meticulously decode the symbols and notations employed in schematics, making them approachable even for beginners. Moreover, delving into the realm of PCB layouts will empower you to position components with precision, guaranteeing the harmonious functioning of your circuit as envisioned.

Soldering Techniques

Soldering is an art. Whether you’re using drag soldering for ICs or reflow soldering for surface-mount components, mastering this skill is crucial. This section will provide detailed instructions, tips, and tricks to ensure your soldering is clean, efficient, and durable.

Using Flux and Solder

Flux is the unsung hero of soldering. It cleans the surfaces and ensures a strong bond between the solder and the components. This section will delve into the types of flux available, their applications, and tips on using solder wire effectively to create perfect joints.

Troubleshooting Common Issues

Even seasoned assemblers encounter issues. Solder bridges, cold joints, or misplaced components can disrupt your circuit’s functionality. This section will highlight these common problems, offering solutions and tips to rectify them, ensuring your PCB works flawlessly.

Testing and Quality Control

Once assembled, testing your PCB is paramount. This section will introduce you to continuity tests, voltage checks, and other quality control measures to ensure your assembly meets the highest standards.

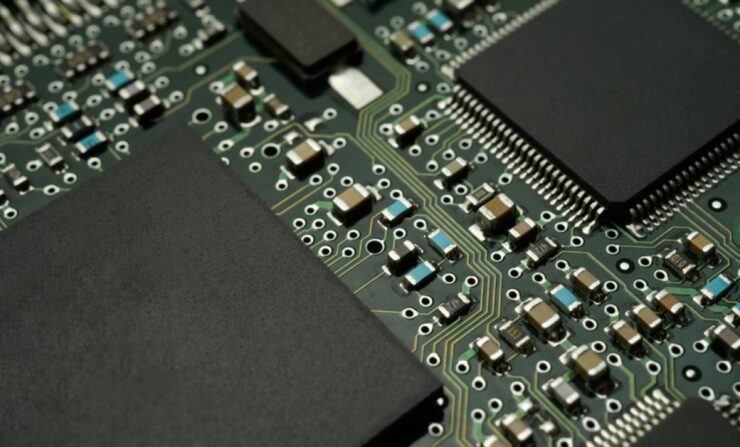

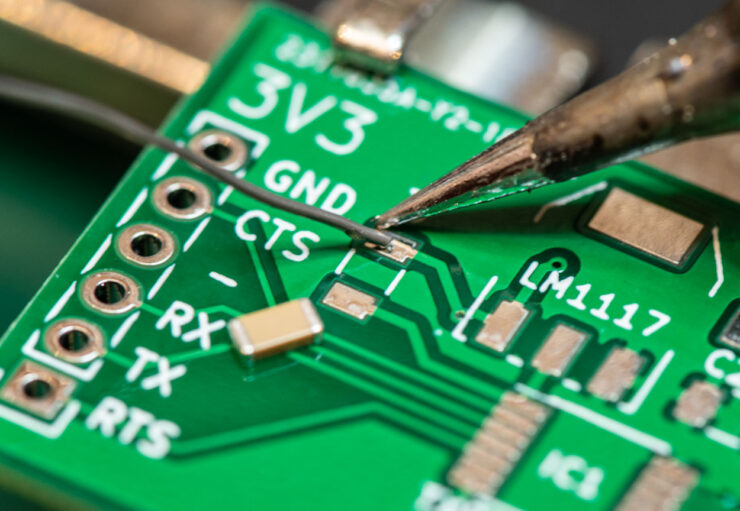

Introduction to SMT Soldering

Surface-Mount Technology (SMT) soldering is becoming increasingly prevalent due to the miniaturization of electronic devices. This section will introduce you to SMT, comparing its advantages and challenges to traditional through-hole soldering.

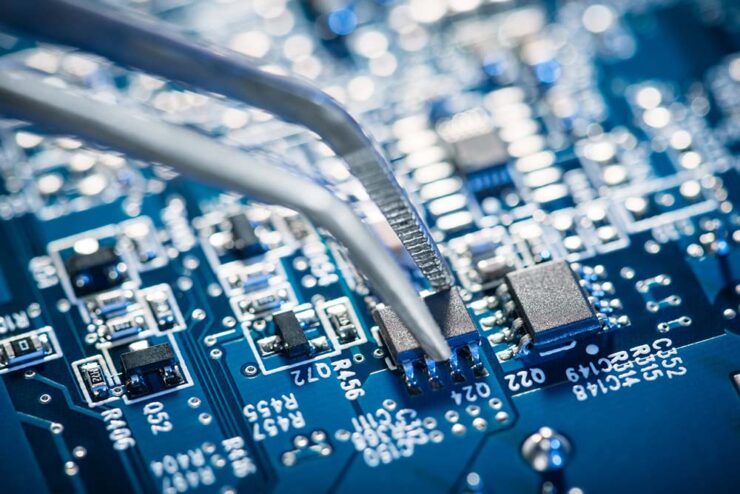

SMT Soldering Techniques

SMT components are tiny, requiring precision and patience. This section will guide you step-by-step through the SMT soldering process, from handling minuscule components to placing them accurately on the PCB.

Advanced Tips for Efficient Assembly

As you progress, you’ll seek ways to enhance your efficiency. This section will introduce advanced tools like soldering stations and magnifying tools and discuss techniques to streamline your assembly process further.

Resources for Learning and Practice

The journey of learning never ends. This concluding section will recommend online resources, tutorials, and courses to deepen your understanding. Plus, we’ll suggest practice projects to hone your skills further.

Summary

Embarking on the journey of PCB assembly is both challenging and rewarding. With this comprehensive guide, you’re well-equipped to navigate the intricacies of this field. Whether you’re pursuing a career or exploring a hobby, the world of PCB assembly awaits you. Dive in, keep learning, and happy assembling!