Remember when your truck was new and everything just worked perfectly? The engine had tons of power, acceleration was smooth, and you could pull heavy loads without any problems. Over time, things start to change. Your truck doesn’t feel as strong as it used to, and you find yourself pushing the gas pedal harder to get the same response you used to get easily.

This happens to every truck eventually, but it doesn’t mean you need to accept poor performance or start shopping for a replacement. Most trucks that feel tired and sluggish can be brought back to nearly new performance with the right attention and repairs. The key is understanding what makes trucks lose their edge and knowing how to fix those problems.

Why Trucks Lose Their Edge

Trucks don’t usually break down all at once. Instead, they slowly lose performance as various parts wear out or get dirty. You might not notice the change day to day because it happens gradually, but over months or years, the difference becomes significant.

The fuel system is often where problems start. Fuel filters get clogged, fuel pumps work harder, and the parts that spray fuel into the engine start wearing out. When these components aren’t working properly, your engine doesn’t get the clean fuel it needs in the right amounts at the right time.

Air intake systems also collect dirt and debris over time. When your engine can’t breathe properly, it loses power and efficiency. Dirty air filters, clogged intake tubes, and buildup in the throttle body all make your truck work harder for less performance.

Engine internals wear out too, but usually more slowly than fuel and air system components. Still, after years of use, even well-maintained engines start to show their age through reduced compression, worn rings, and other internal wear.

The Fuel System Makes All the Difference

Most truck performance problems start with fuel delivery issues. Your engine is basically a big air pump that mixes air and fuel to create power. When the fuel side of that equation isn’t working right, everything else suffers.

Old fuel filters restrict flow and make fuel pumps work harder. Dirty fuel injectors don’t spray fuel evenly, leading to rough running and poor power. Water or contamination in fuel tanks can cause ongoing problems that get worse over time.

Replacing these components usually makes a dramatic difference in how your truck runs. Clean fuel filters allow proper flow. New fuel injectors restore proper spray patterns and fuel delivery. For trucks with high mileage or hard use, upgrading to better quality components often provides even better results than original equipment.

When dealing with diesel trucks, fuel injection quality becomes even more important. High-quality fuel injectors for cummins truck applications can restore power and efficiency that seemed permanently lost. These engines respond particularly well to fuel system improvements because of their high-pressure injection systems.

Air Flow and Breathing Issues

Engines need to breathe, and restricted airflow is another major cause of poor performance in aging trucks. This problem starts with simple things like dirty air filters but can include more complex issues throughout the intake system.

Air filters are easy to replace and make an immediate difference when they’re dirty. But other parts of the air intake system need attention too. Intake tubes can develop cracks or loose connections that let unfiltered air into the engine. Mass airflow sensors get dirty and send wrong signals to the engine computer.

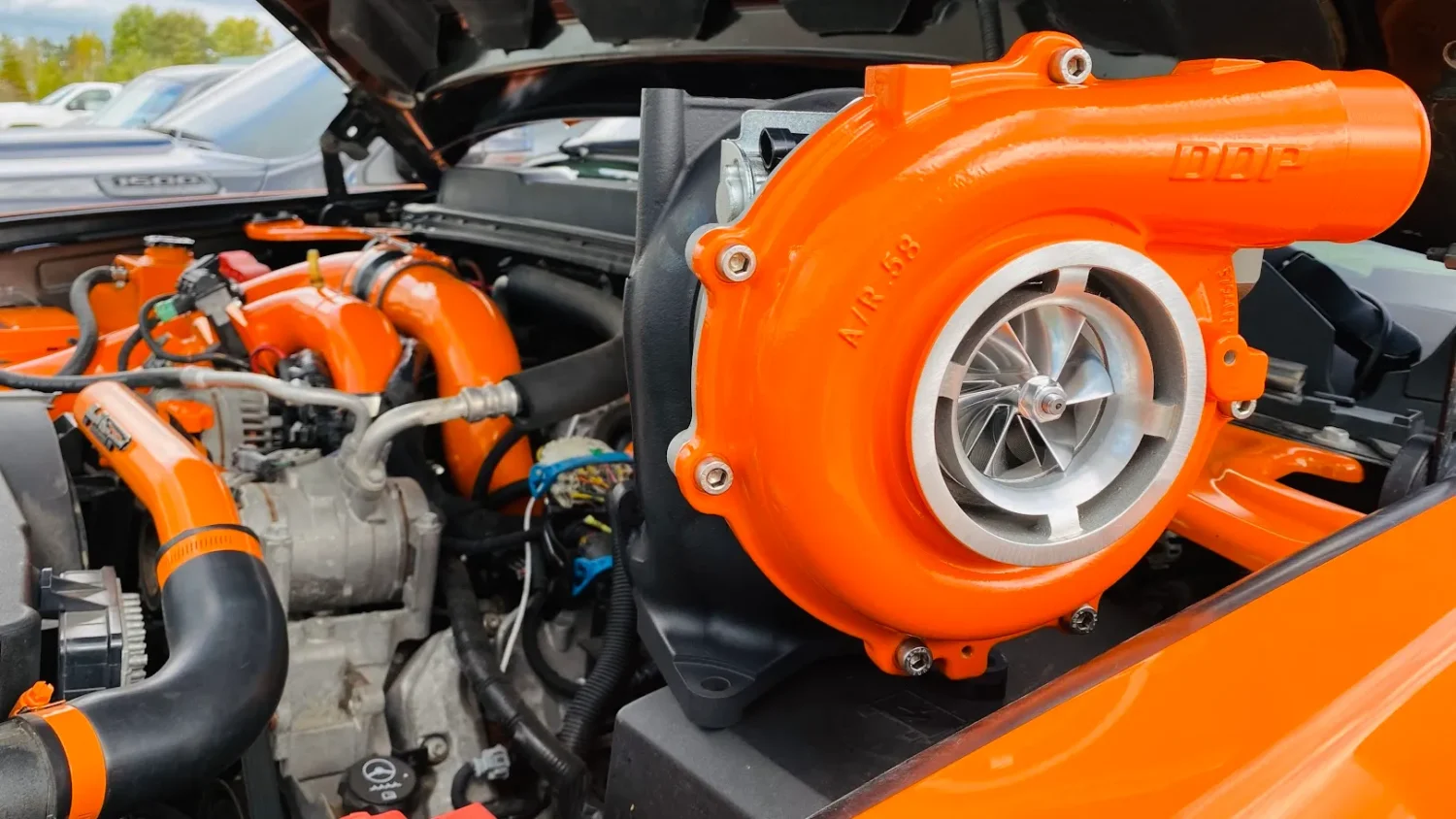

Turbochargers in diesel trucks can develop problems that seriously affect performance. Worn turbos don’t build proper boost pressure, leaving the engine feeling weak and unresponsive. Intercoolers can get clogged with oil or debris, reducing the efficiency of the compressed air.

Cleaning or replacing these components often brings back power that owners thought was gone forever. The difference is usually noticeable immediately after proper repairs are completed.

Engine Internals and Compression

While fuel and air systems cause most performance problems, sometimes the issue is inside the engine itself. Worn piston rings, valve problems, or carbon buildup can reduce the engine’s ability to create power efficiently.

Compression tests can reveal these kinds of problems. Low compression in one or more cylinders indicates internal wear that might require major repairs. But not all internal problems require engine rebuilds. Carbon cleaning, valve adjustments, and other services can sometimes restore much of the lost performance.

Oil changes become more important as engines age. Dirty oil contributes to internal wear and reduces engine efficiency. Using high-quality oil and changing it more frequently can help older engines maintain better performance longer.

Transmission and Drivetrain Factors

Sometimes what feels like engine problems is actually transmission or drivetrain issues. Transmissions that don’t shift properly or slip under load make the whole truck feel weak and unresponsive.

Automatic transmission fluid breaks down over time and needs replacement. Dirty transmission fluid can cause shifting problems, slipping, and poor performance. This is often overlooked during regular maintenance but makes a huge difference in how the truck feels to drive.

Differential and transfer case fluids also need periodic replacement. While these components don’t directly affect engine power, problems here can make the truck feel sluggish or cause vibrations that make the whole vehicle feel tired.

The Right Parts Make a Difference

When restoring truck performance, the quality of replacement parts matters. Cheap parts might fix immediate problems but often don’t last or perform as well as better quality components. This is especially true for critical systems like fuel injection and air intake.

OEM parts usually provide reliable performance that matches original specifications. But aftermarket upgrades can sometimes provide better performance than original equipment, especially for trucks that work hard or have high mileage.

The key is matching parts quality to your needs and budget. Daily drivers might do fine with standard replacement parts, while work trucks or performance applications benefit from higher quality components that can handle more stress.

Professional Diagnosis Saves Time and Money

While some truck performance problems are obvious, others can be tricky to diagnose correctly. Modern trucks have complex computer systems that can provide valuable diagnostic information when problems occur.

Professional diagnostic equipment can identify specific problems quickly instead of guessing and replacing parts randomly. This saves money by fixing the right problems the first time and prevents unnecessary repairs.

Some problems require special tools or knowledge to fix properly. Fuel injection systems, turbochargers, and engine management systems often need professional attention to get the best results.

Bringing Back That New Truck Feel

The goal of performance restoration isn’t just fixing problems but bringing back the driving experience you remember from when your truck was new. This means addressing all the systems that affect how the truck feels, not just the most obvious problems.

A comprehensive approach usually works better than fixing one thing at a time. Combining fuel system cleaning, air intake service, and other maintenance creates a bigger improvement than individual repairs spread over time.

Regular maintenance after restoration helps maintain the improved performance. Clean filters, quality fluids, and periodic service keep trucks running strong much longer than neglect followed by major repairs.

Most trucks that feel tired and worn out can be restored to much better performance with proper attention to fuel systems, air intake, and other key components. The difference is usually dramatic and makes driving enjoyable again instead of frustrating.