What’s the real driving force behind the machines that move entire industries? It’s not just the engine or the frame. It’s the parts you don’t often see or think about, like the PTO pump.

In the world of heavy-duty vehicles, raw horsepower means nothing if you can’t control it, redirect it, and turn it into something useful. That’s where a PTO (Power Take-Off) pump steps in.

These underrated mechanical players are crucial to the functionality of a huge range of vehicles, from dump trucks and concrete mixers to tow trucks and cranes. They help convert engine power into hydraulic force, which then drives a whole range of secondary systems and equipment.

Let’s break down exactly how they work, what they’re used for, and why they’re essential if you want your fleet to do more without overworking your gear. This is your comprehensive guide to how PTO pumps boost output.

What Is a PTO Pump?

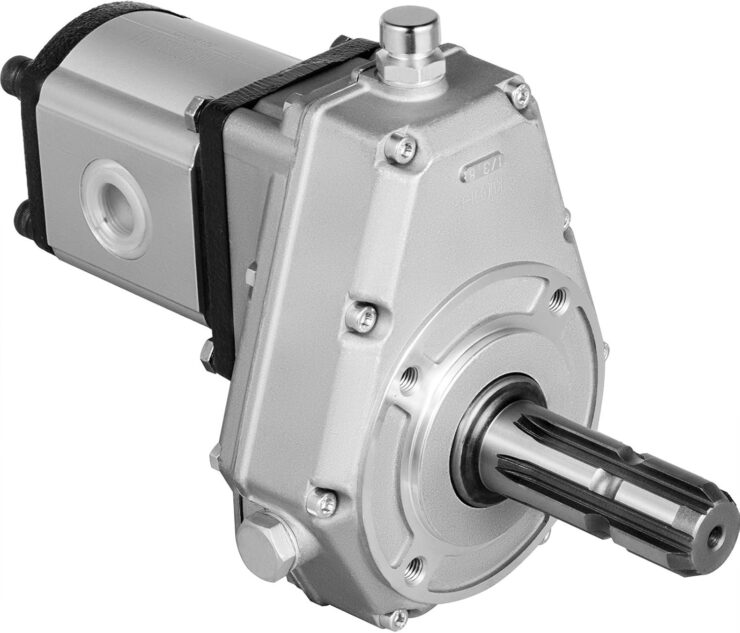

At its simplest, a PTO pump is a mechanical device that taps into the engine’s power and redirects it to run auxiliary components. Think of it as a link between the vehicle’s engine and any equipment that needs hydraulic power.

Instead of relying on a separate engine or motor to drive tools or attachments, the PTO pump allows the main engine to take care of everything, making the whole system more efficient and compact.

It typically connects to the transmission or engine directly. When engaged, it powers hydraulic systems like lifts, cylinders, or motors. Depending on the setup, it can be engaged while the vehicle is stationary or moving.

Why They Matter in Heavy-Duty Applications

Heavy-duty vehicles don’t just drive — they lift, dig, push, haul, spin, and more. A PTO pump enables all of that. Without a reliable PTO system, a truck might be able to carry a load, but it wouldn’t be able to unload it. A cement truck could drive to site, but couldn’t spin its drum. A tow truck could arrive at the scene, but not lift a vehicle. It’s not an optional feature — it’s a critical system.

Here’s what makes PTO pumps so valuable in heavy-duty applications:

- Power efficiency – They harness existing engine output, removing the need for additional motors.

- Compact design – Because they use existing engine infrastructure, they save space and reduce weight.

- Versatile use – PTO pumps can power a wide variety of systems, from hydraulic arms to compressors.

- Greater uptime – A solid PTO system reduces reliance on external equipment, meaning fewer delays and simpler logistics.

Common Applications in the Field

PTO pumps aren’t reserved for one or two niche vehicle types. They’re used across many industries that rely on heavy equipment. Some of the most common setups include:

- Tippers and dump trucks – To raise and lower hydraulic beds for unloading materials.

- Cranes and lifts – For powering the boom, winch, or elevation mechanisms.

- Garbage trucks – Running compactors and lifting arms for collection.

- Concrete mixers – Spinning the drum consistently to keep material from setting.

- Tankers – Driving pumps that load or unload liquids or semi-liquids.

- Tow trucks – Operating winches, hydraulic beds, or lift arms to secure and move vehicles.

The ability to tap into engine power to perform all of these tasks means fewer moving parts, lower maintenance costs, and smoother operation.

How They Actually Work

While the end result is straightforward, the mechanics are precise. The PTO unit attaches to the vehicle’s transmission or engine. When the operator activates the PTO (manually or electronically), it begins turning a shaft connected to the pump.

The pump then draws in hydraulic fluid, pressurises it, and sends it through hoses to drive a motor, cylinder, or actuator. This setup allows an incredible range of movement and lifting power, all controlled from within the cab or an external control panel.

Some systems are engaged while stationary, others can function while the vehicle is in motion — ideal for tasks like operating a concrete mixer on the road. Hydraulic pressure, flow rate, and duty cycle all depend on the type of pump and the engine it’s drawing power from. That’s why matching the right PTO pump to the vehicle and job type is essential.

Key Factors for Choosing the Right PTO Pump

Choosing a PTO pump isn’t just about finding something that fits. It’s about making sure it can handle the work consistently without compromising other vehicle systems. Some things to consider:

- Vehicle specs – Different transmissions and engines require specific PTO connections and torque ratings.

- Hydraulic demands – What pressure and flow does the application need? Undersizing leads to poor performance. Oversizing wastes fuel.

- Mounting orientation – Side-mounted, rear-mounted, or engine-driven setups all impact installation and performance.

- Duty cycle – Some pumps are designed for occasional use, others for non-stop operation.

Skimping on any of these details can lead to poor system performance or premature failure. It’s not just about power — it’s about pairing the right components.

Maintenance Matters

Like any mechanical component, PTO pumps require proper maintenance to keep them working at peak efficiency. This includes:

- Regularly checking for hydraulic fluid leaks

- Ensuring filters are clean and changed when needed

- Monitoring pressure and flow for signs of pump wear

- Keeping mounting bolts tight and components aligned

Neglect here can lead to more than just a minor inconvenience. It can sideline your vehicle or cause damage to expensive hydraulic systems. So while they’re designed to be durable, they’re not “set and forget.”

The Hidden Backbone of Productivity

PTO pumps are not the biggest or most noticeable part of the vehicle. But they do the grunt work that makes a lot of the real action possible. Whether you’re operating a fleet or running a single heavy-duty vehicle, understanding how these pumps work — and making sure yours is the right match — makes a major difference.

They’re part of the core system that lets one engine do many things. And in an industry where output, uptime, and control all matter, that kind of smart power conversion isn’t just handy. It’s essential.

Need more from the vehicles you already own? Start by looking at the workhorse within.